By Tim White |

Tim's MX-5 Project: Part 2 - Rust

Part 2 will be heavy on pictures and light on words for obvious reasons. When we last left off, the plan was to get stuck into the rust repairs on the car and make sure it would survive this coming winter. Well, as with any older car, rust is always a concern but is almost always worse than it looks..!

Driver's side.

Credit: By Tim White @mosseuropeltd

Passenger's side.

Credit: By Tim White @mosseuropeltd

Now on the surface neither of these looked too bad. But when you start cutting into the car to find where the bad stuff ends and the good stuff begins, you end up being left with a pretty sizable hole..!

That'll be all three skins on the driver's side then..!

Credit: By Tim White @mosseuropeltd

...and all three on the passenger side as well..!

Credit: By Tim White @mosseuropeltd

So both sides needed a fair bit of work! The driver’s side clearly the worse of the two, but fortunately both were well on the right side of 'salvageable' especially for a DIY-er who’s skilled with a welder. Thankfully, my very good friend Robert is just that person and has a fair bit of experience welding up MX-5s himself. He’s the proud owner of a VERY early NA6 in Mariner Blue which like most cars of its age, has needed some TLC in the form of sheet metal and welding wire. So Robert is definately the right person for the job.

With that, some welding gas, a few power tools and some courage, we went to work.

Credit: By Tim White @mosseuropeltd

First layer patched up with matching gauge metal cut to shape.

Credit: By Tim White @mosseuropeltd

Second layer patched and shaped.

Credit: By Tim White @mosseuropeltd

Third layer grafted, sealed and reshaped (green goo will be explained shortly).

Credit: By Tim White @mosseuropeltd

Outer skin and repair panel grafted in and coated.

Credit: By Tim White @mosseuropeltd

'Whilst we’re in there' undersealing/protecting as much as possible.

Credit: By Tim White @mosseuropeltd

Passenger's Side:

Credit: By Tim White @mosseuropeltd

Layer 2 cut, shaped and welded.

Credit: By Tim White @mosseuropeltd

Outer skin repair panel grafted on.

Credit: By Tim White @mosseuropeltd

The eagle-eyed among you will notice that we didn’t exactly take the best of care when it came to protecting the paint on the car. Ultimately, the car needs paint in the future anyway, so for now the priority is function over form. It’s not the prettiest flower in the bush, but at least she’s solid, and the paint we put down will seal the metalwork up for the winter.

Spraying the driver's side inner sill.

Credit: By Tim White @mosseuropeltd

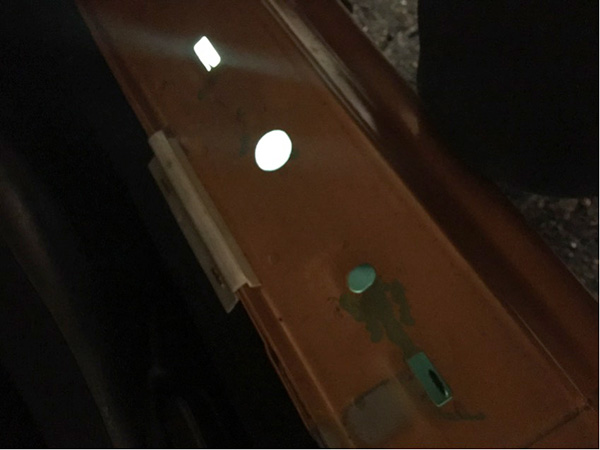

Checking coverage once dry.

Credit: By Tim White @mosseuropeltd

Exhaust & MoT

Out with the old.

Credit: By Tim White @mosseuropeltd

And in with the new!

Credit: By Tim White @mosseuropeltd

Just in the nick of time, MoT tester checking out our handywork the following day!

Credit: By Tim White @mosseuropeltd

Conclusion & The Future

Find more from Tim on Instagram @timbomfg

Keep up with all the latest from Moss Europe on our social pages. |

Loading...

Loading...